Robotic applications

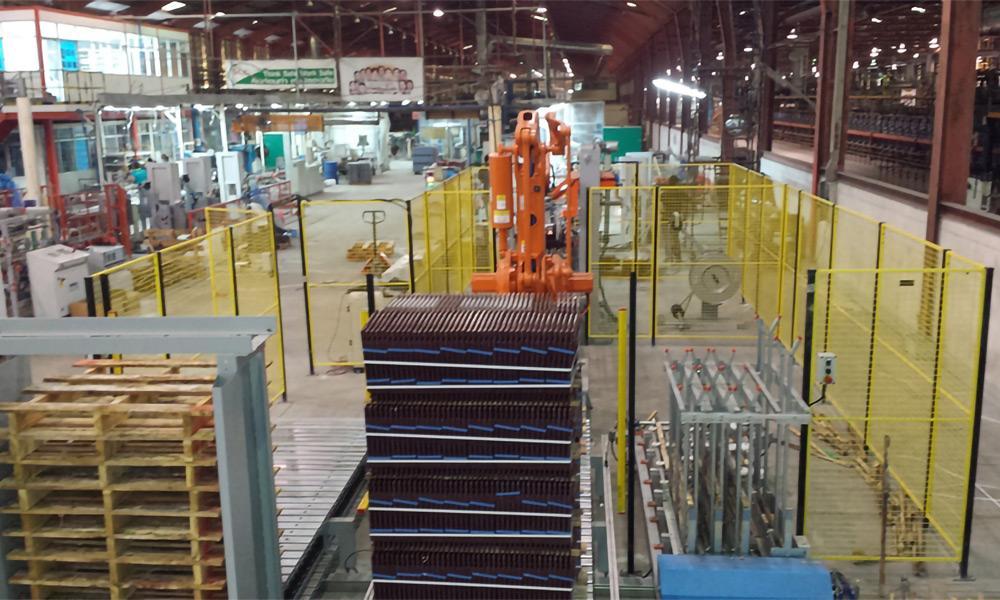

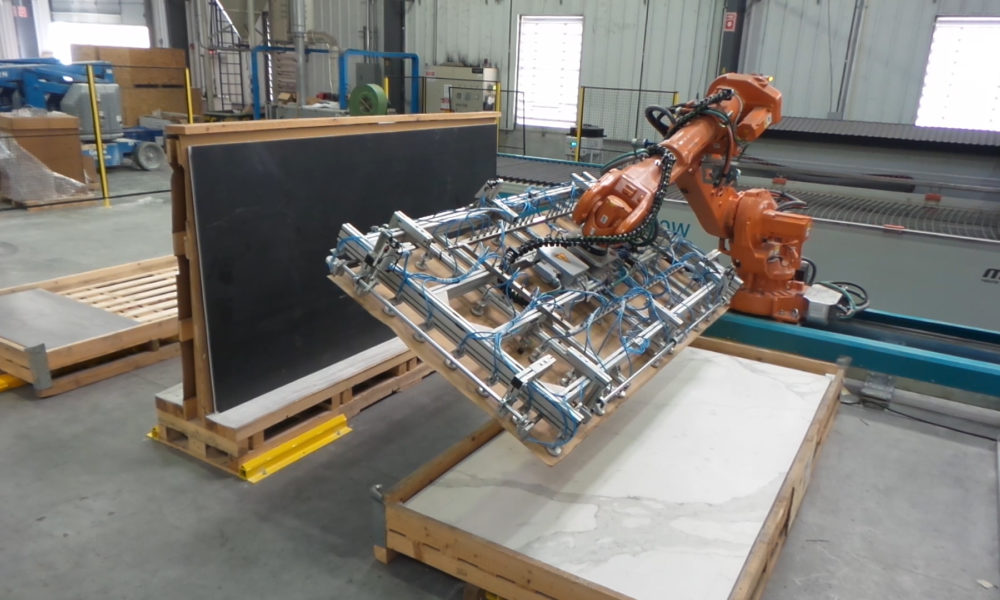

We invest in research and development of technologies in step with the technical evolution of materials whose apex, in the ceramic industry, is today represented by large porcelain stoneware slabs. In the context of large formats, we were among the first companies to propose innovative systems for handling slabs, focusing, where required, on the high performance skills of anthropomorphic robots.

Today, our robotic applications are tailor-made for end-of-line systems, sorting, packaging and palletizing of large materials, both inside and outside the ceramic sector.

The robotic integrated automation systems are able to manage all the operations of a processing cycle of any material and format, from picking up the product, to handling it, to final storage.

Robotic applications for:

Packaging and Palletizing

Automation lines for packaging and palletizing materials of all types (bricks, ceramics and marble) and size (from small to large and very large formats). The ad hoc integration between mechanical tools and anthropomorphic arms allows the material to be packed automatically and to prepare containers and pallets for the housing of materials in an adequate and fast way.

Handling

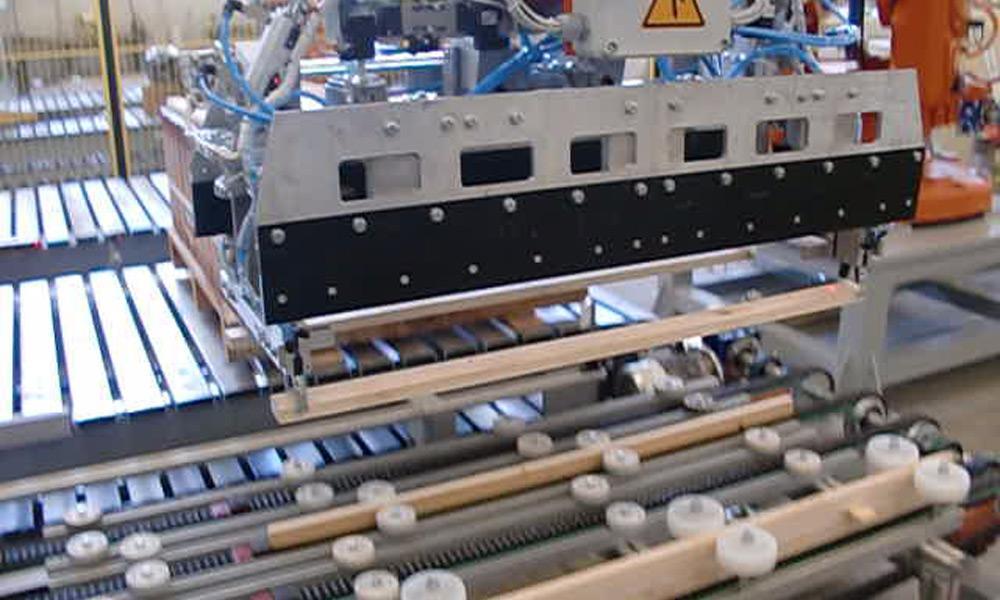

Robotic automation systems for the management of large and very large formats.

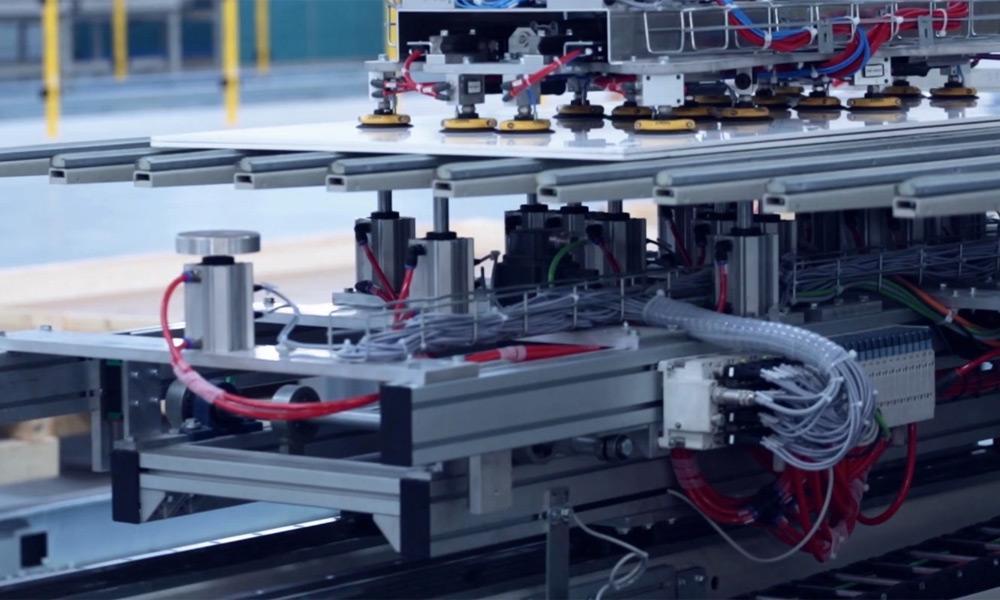

An example is the just-in-time model for on-site cutting in the desired format, reducing time, costs and prolonged storage in the warehouse. The design of electromechanical tools integrated with robots allows the picking of slabs from horizontal or vertical containers, precise positioning on the cutting machine through innovative centering mechanisms, perfect management of cutting, washing, drying and storage operations.

Picking and placing

Each automated processing cycle requires precise product handling, from one work area to another on the line and according to specific criteria, which respect the characteristics of the format or type of material currently processed. For large formats, SIMEC has developed highly versatile and configurable robotic machines for the selection, picking and positioning of the product, easily integrated with other pre-existing automation systems.

The advantages of SIMEC robotic applications

- Flexibility and precision

- Just-in-time processing (for example for on-site cutting in the desired format)

- Multifunctional properties of the application for ad hoc operations

- Increased production

- Increased accuracy

- Safety implementation

- Reduction of time and stock in the warehouse

- Cost reduction

Ideal for: