Special all-in-one conveying systems

The client

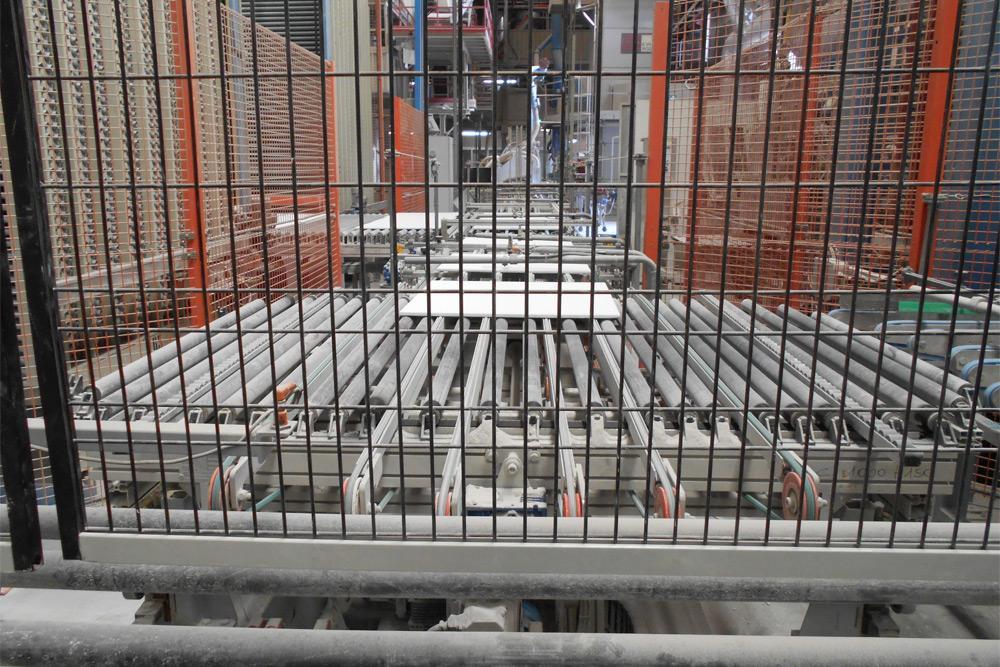

A large ceramics manufacturer had the need to move and manage in a very flexible way pieces of different sizes and types (fired and raw materials) along the entire production line.

The challenge

The project consisted of creating solutions that had to be highly flexible in the function and could manipulate materials of any format along the line. SIMEC put in place all its experience in the field of conveying and handling of materials to design a machine that, on its own, manages pieces that are also much diversified.

The solution

We have created two systems for real-time management of any format, with the option of being able to determine how and when to handle the piece along the conveyor line. Our solution allows every type of handling and the managed pieces can be of any size, from the smallest to the very large. Depending on the required positioning of the piece (longitudinal, transverse, rotated, lifted, etc.), the entire system manages all the necessary handling operations that normally would include different machines.

Results and development

The system solves several critical issues along the production line, such as, for example, the space taken up by the positioning of different machines and the possibility of autonomously managing the movement of different pieces according to their processing and their format.